HVS TOOLS - A Company of Excellent Services

Welcome to HVS Tools, your trusted manufacturer of high-quality Carbide Form Tools. With years of industry experience, we specialize in delivering precision-engineered solutions for all your industrial needs. At HVS Tools, we understand the importance of reliability and strength in fasteners. Quality is at the heart of everything we do. Our advanced manufacturing processes and stringent quality control measures ensure that each product leaving our facility meets the highest standards of excellence.

Vision

Our vision is to be the leading global provider of precision-engineered Carbide Form Tools. We aim to set the benchmark for quality and reliability in the industry, driving innovation and excellence in every product we create.

Mission

Our mission at HVS Tools is to deliver unparalleled quality and performance in every tool and fastener we manufacture. We are dedicated to providing our customers with robust, reliable solutions that meet their precise industrial needs.

Core Values

We prioritize superior quality in every product, ensuring durability and precision through stringent quality control measures.Our customers are at the center of everything we do.

Products & Services

Cutting Tools

Carbide Form Tools

Grooving Tools

Power Drill

Taps

Fixtures And Gauges

Cutting tools

Cutting tools are vital instruments in the machining and manufacturing sectors, designed to remove material from a workpiece through processes such as cutting, shearing, and grinding. These tools come in various types, including single-point tools like lathe and boring tools, and multi-point tools such as milling cutters and drill bits. The material composition of cutting tools significantly influences their performance and durability, with common materials including high-speed steel (HSS), carbide, ceramics, cubic boron nitride (CBN), and diamond.

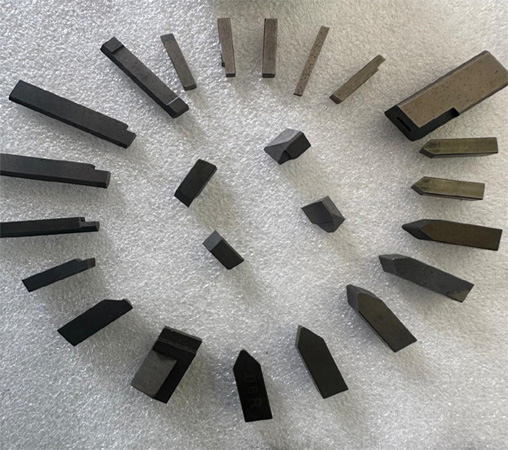

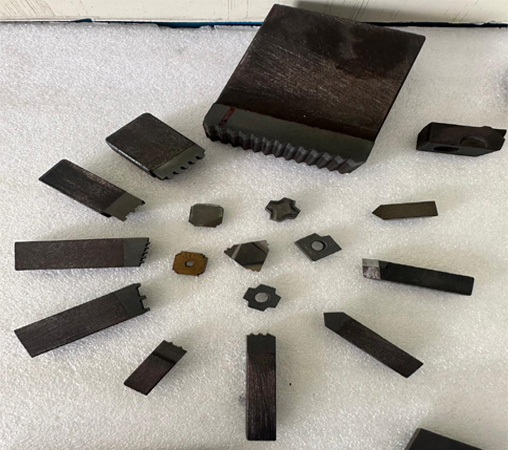

Carbide Form Tools

Carbide Form Tools are cutting tools made from tungsten carbide, a hard, wear-resistant metal compound. They are created by combining tungsten carbide particles with a specific amount of cobalt, which acts as a binding agent that holds the tungsten carbide particles together. Carbide Form Tools are used in HVS tools manufacturing company for various purposes. They are created by combining tungsten carbide particles with a specific amount of cobalt, which acts as a binding agent that holds the tungsten carbide particles together.

Grooving Tools

Grooving tools are essential in various machining processes, used primarily to create grooves on a workpiece. These tools are indispensable in the manufacturing and engineering sectors due to their ability to produce precise and accurate grooves, which are crucial for fitting parts together, facilitating assembly processes, or accommodating seals and o-rings.

Power Drills

Power drills are electric or pneumatic tools used to drill holes in various materials, including wood, metal, concrete, and plastic. At HVS Tools Manufacturing Company, we understand the importance of using high-quality power drills to achieve precision, efficiency, and reliability in various industries. Our power drills are designed to meet the demanding requirements of modern manufacturing, providing exceptional performance, durability, and versatility.

Taps

Taps are cutting tools used to create internal threads in a workpiece, allowing for the creation of strong, reliable joints and assemblies. At HVS Tools Manufacturing Company, we understand the importance of using high-quality taps to achieve precision, efficiency, and reliability in various industries. Our taps are designed to meet the demanding requirements of modern manufacturing, providing exceptional performance, durability, and versatility.

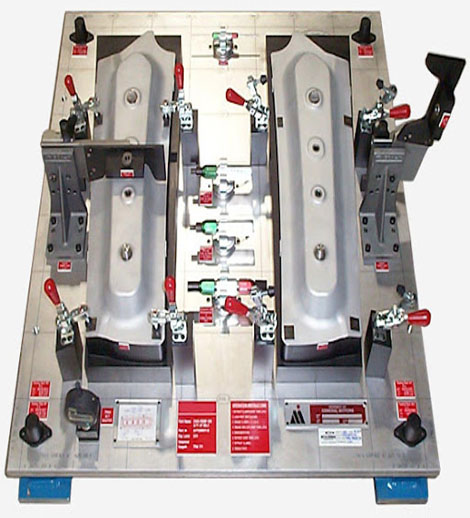

Fixtures And Gauges

HVS fixtures and gauges ensure precise measurement and inspection, reducing errors and improving product quality. At HVS Tools Manufacturing Company, we understand the importance of using high-quality fixtures and gauges to achieve precision, efficiency, and reliability in various industries. Our fixtures and gauges are designed to meet the demanding requirements of modern manufacturing, providing exceptional performance, durability, and versatility.

Year of Establishment

Completed Projects

Our Employees

Quality Assurance

Manufacturing Processes

Design & Development

- Conceptualization: Begin with understanding customer requirements and designing products that meet their specific needs.

- Prototyping: Create detailed technical drawings and prototypes using advanced CAD software to ensure precision and functionality.

Selecting & Preparing Materials

- Raw Materials: Source high-quality carbide and other essential materials.

- Preparation: Cut, shape, and treat raw materials as per design specifications to prepare them for the manufacturing process.

Production

- Machining: Utilize state-of-the-art CNC machines and other advanced equipment to manufacture tools with high precision.

- Forming and Shaping: Implement various forming processes like forging, casting, and extrusion to achieve the desired shape and dimensions.

Heat Treatment & Finishing

- Heat Treatment: Apply heat treatment processes such as annealing, quenching, and tempering to enhance the strength and durability of the products.

- Finishing: Perform surface finishing processes like grinding, polishing, and coating to ensure smooth, corrosion-resistant surfaces and precise dimensions.

Quality Control and Inspection

- Testing: Conduct rigorous quality control tests at every stage of production, including dimensional checks, hardness tests, and performance evaluations.

- Final Inspection: Perform a comprehensive final inspection to ensure that each product meets the highest standards of quality before packaging and shipping to customers.