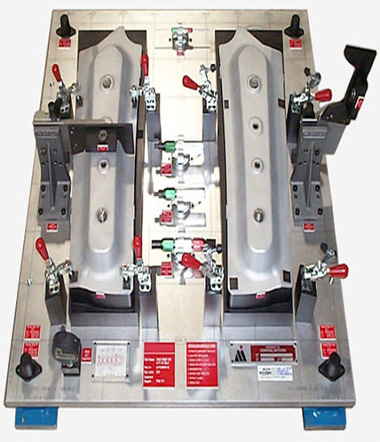

Fixtures and gauges are crucial components in manufacturing and quality control processes, ensuring precision, repeatability, and efficiency. Fixtures are specialized tools designed to securely hold, support, and locate a workpiece during machining operations, minimizing the risk of errors and enhancing the accuracy of cuts, drills, and other procedures. They are custom-made for specific tasks, aligning the workpiece in a precise position and orientation, thereby facilitating consistency across production runs. Gauges, on the other hand, are measuring instruments used to inspect and verify the dimensions, shape, and other geometric characteristics of a workpiece. They help in maintaining strict adherence to design specifications and tolerances, ensuring that each component meets the required standards. Together, fixtures and gauges play a vital role in streamlining production, reducing waste, and ensuring high-quality outputs in various industries, from automotive and aerospace to electronics and consumer goods. Their use enhances not only the efficiency of the manufacturing process but also the reliability and performance of the final products.

Fixtures Gauges

Home/ Fixtures Gauges