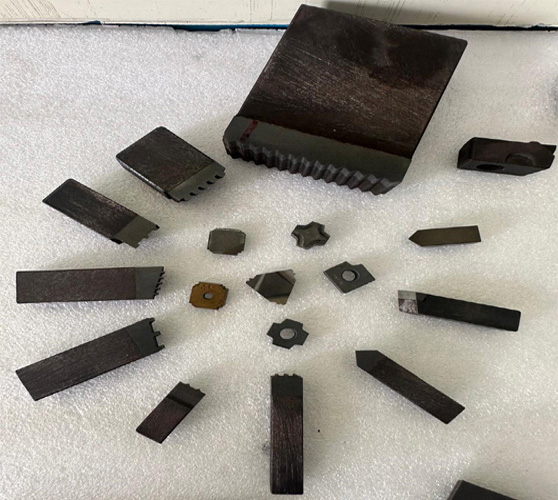

Carbide Form Tools are a cornerstone of modern machining, renowned for their exceptional hardness and wear resistance, which make them ideal for high-speed cutting applications. Composed primarily of tungsten carbide particles bonded with a metallic binder, typically cobalt, these tools outperform traditional high-speed steel (HSS) tools in both durability and cutting speed. The remarkable hardness of carbide enables it to maintain a sharp cutting edge even at elevated temperatures, allowing for efficient machining of hard materials such as stainless steel, cast iron, and non-ferrous metals. Additionally, Carbide Form Tools can be coated with materials like titanium nitride (TiN) or titanium aluminum nitride (TiAlN) to further enhance their performance by reducing friction and increasing heat resistance. This combination of properties results in longer tool life, higher productivity, and superior surface finishes on machined parts. Consequently, Carbide Form Tools are indispensable in industries ranging from automotive and aerospace to die and mold making, where precision and efficiency are paramount.

Carbide Form Tools

Home/Carbide Form Tools